| PHONE: (208) 783-0200 |

|

|

CRESCENT MINE PROJECT - NEW JERSEY MILL JOINT VENTURE :: CRESCENT SILVER - IDAHO’S PREMIER SILVER MINE PROPERTIES OVERVIEW - GEOLOGY - MINERAL RESOURCE ESTIMATION - MINING METHODS - MILLING - PERMITTING

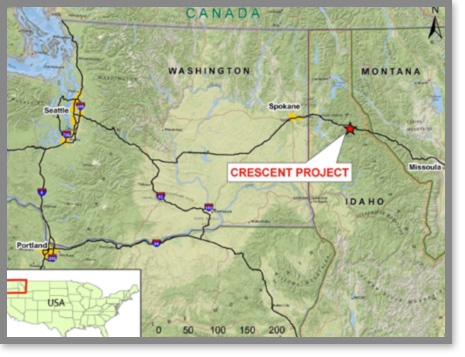

Crescent Silver, LLC owns 100% of the Crescent Mine located approximately 4 miles southeast of Kellogg, Idaho in Shoshone County about 75 miles east of Spokane, Washington. The Crescent Mine includes 1,280 acres of patented mining claims and a vested interest in the New Jersey Mining Company Mill (34.8%) with an agreement for a right to the first 70% of the mill’s 440 ton per day capacity. The mine and mill are fully permitted and permits are in compliance. Because the mine is on patented mining claims (privately-owned land), only a limited number of environmental permits are required for mining and milling operations.

Test mining was also conducted in 2011 and 2012 with mechanized equipment on three separate sublevels of the South Vein to determine vein characterization and optimal mining methods for future production. Tetra Tech was contracted to provide an updated NI 43-101 PEA Technical Report. This report was completed in August 2015. The results of this assessment were positive suggesting an advancement of the project to preliminary-feasibility.

The mineralized veins of the Project are typical “Silver Belt” veins, and are composed of siderite, quartz, and various sulfides including pyrite, tetrahedrite, chalcopyrite, arsenopyrite and galena. Most of the silver is found within the tetrahedrite, which is argentiferous (silver bearing) throughout the district. It generally contains between 2% and 6% silver by weight. Substantial amounts of silver are also recovered from galena. Secondary oxide minerals that have been noted historically include cerargyrite, native silver, cerussite, malachite, cuprite, argentite, chalcocite, and pyromorphite. Both the Alhambra and South Veins are partly oxidized. The Alhambra fault and vein zone displays a normal oxidation pattern from surface to a depth of 250 to 300 ft below surface. The South vein has a 200 to 400 ft wide zone of oxidation plunging down-dip, parallel to the mineralization. The oxidation fluids appear to be following the mineralized portion of the structure, or may be an indication of an intersecting fault. Mineralized zones in the district generally have more vertical than lateral extent. Historic stoping in the Project suggests that the higher-grade mineralization has vertical: lateral ratios between 2.5:1 and 4:1. The mineralized zones plunge down-dip, parallel to the shear lineation developed during the same deformation that brackets the mineralization.

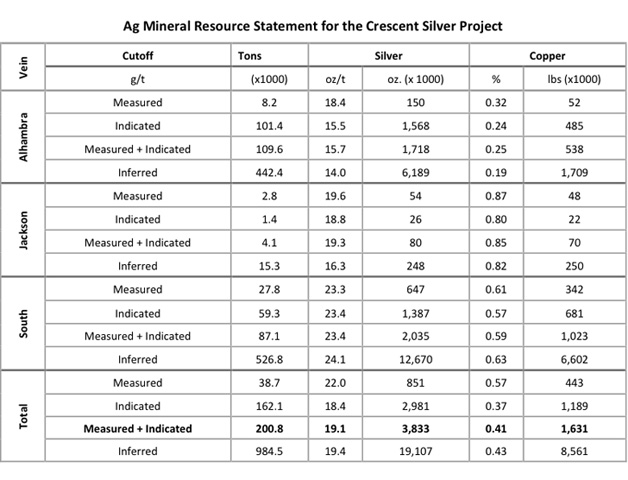

The mineral resource from the Tetra Tech August 2015 PEA is shown in the following table at a silver

1.) Underground mining costs of $145 per ton

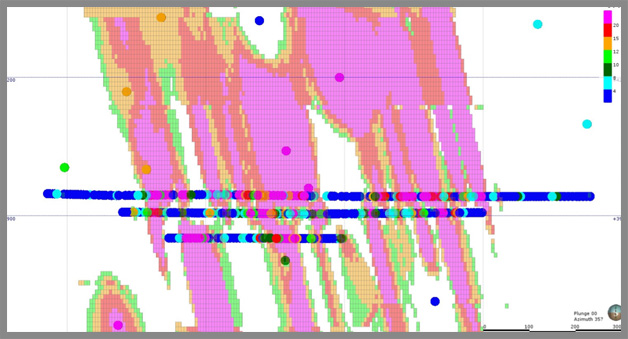

South Vein Ag Long Section

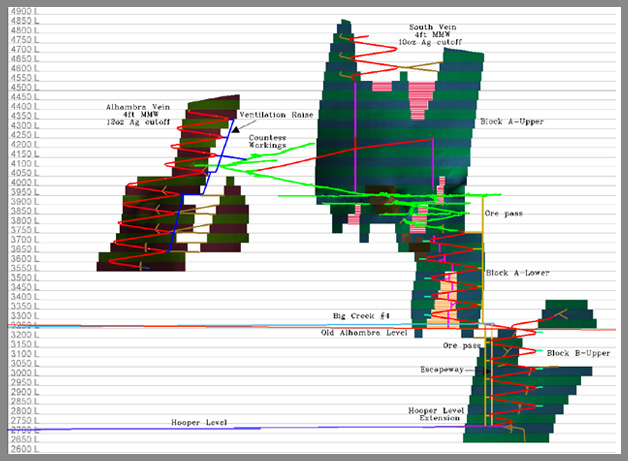

The Crescent Mine would use an overhand cut-and-fill method, with a new series of stopes started every 50 vertical feet in the veins to allow multiple levels to operate concurrently. In this method, the first stope would be started as a sublevel 10 ft high from a central access point. The sublevel would be driven in both directions along strike to the end of the ore zone or 200 ft away from the access point, whichever comes first. The sublevel would then be backfilled with cemented fill, and a second sublevel would be breasted down on top of the fill. This would continue until the mining of 5th sublevel is completed. The mine would use three variations of this method, depending on the width of the ore zone and where the ore zone is located in the mine. The mine plan developed for the Crescent Mine targets the wider and higher grade ore zones for early development. These zones are located above the Big Creek #4 adit extension between the 3300 elevation and 3700 elevation and are part of the resources known as South Vein-A Block-Lower. To access this area for early production, the Big Creek #4 adit would be extended to the South Vein, and the Countess Decline ramp system extended down to the Big Creek level. These development efforts would proceed concurrently and are scheduled for 12 months of development to access the mining areas. Once the two development efforts are connected, stope access and production can then be started using truck haulage out the Big Creek Portal. The connection of the Big Creek #4 adit with the main ramp system will complete the main ventilation path and secondary escapeway necessary to begin production.

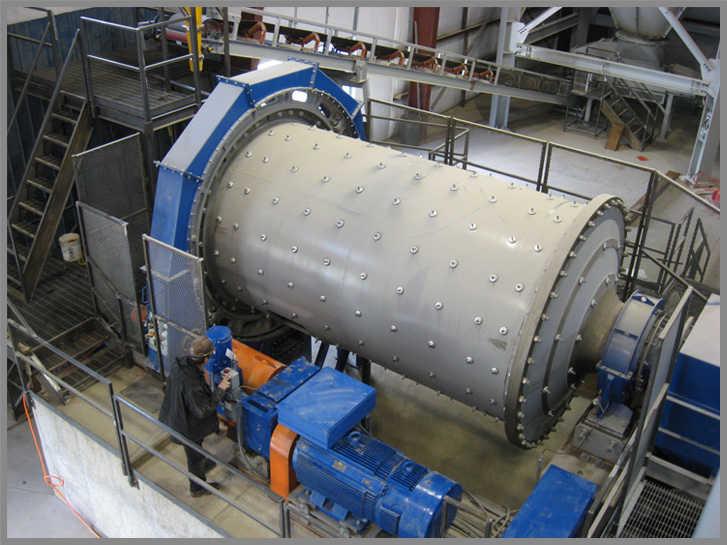

Mine Longitudinal Schematic Looking South

Run-of-Mine (RoM) ore that would be produced at the Project would be sent to the Mill. The Mill is a permitted and operational process tolling (custom milling) facility owned by; the New Jersey Mining Company (NJMC), 65.2% and Crescent (34.8%). The Mill is operational and can operate at up to 440st/day, including tailings storage. It is located less than 4 miles from the Crescent Mine Property. Crescent is guaranteed; up to 330 st/day, or 75% of plant capacity for the life of the Mill, any excess capacity if available, and access to the tailings for use for backfill. The current plan would be for the Crescent Mine to provide 250st/day of run-of-mine ore to the Mill. Crescent ore feed is crushed to -3 inches in a jaw crusher. Material over 2 inches is screened off and sent to a cone crusher in a closed loop. Screen undersize drops into a 385 ton fine mill feed bin. The fine mill feed bin discharges onto the bin discharge belt conveyor which, in turn, discharges onto the ball mill feed belt conveyor. Lime is added to the mill feed to adjust pH. The ball mill is a 250 kW Marcy-type ball mill that is 8 ft in diameter and 13 ft long. The ball mill discharge is pumped to a hydro-cyclone where cyclone underflow reports back to the mill for additional grinding, and cyclone overflow is conveyed via gravity to the rougher flotation cells. Tailings from the rougher flotation circuit are pumped into two Deep Cone Thickeners (DCT) operated in parallel to produce paste tailings. Thickener overflow is piped to a process water storage tank. Underflow from the paste thickeners is pumped to a tailings impoundment area about 500 ft east of the mill building. In 2012 a bulk sample of 12,000 short tons were mined from the south vein and processed at the New Jersey Mill. Recoveries averaged 94% after the commissioning period (August 1st through September 3rd) when the mill was operating 24 hours per day, indicating that the Mill achieving the design goals for treating Crescent Mine ore. The mine and mill are fully permitted and permits are in compliance. Because the mine is on patented mining claims (privately-owned land), only a limited number of environmental permits are required for mining and milling operations.

OVERVIEW Crescent Silver has 65% production interest in the New Jersey Mill CAPACITY SILVER LOCATION

|

|

Crescent Silver owns and operates the Crescent Mine, in Idaho’s prolific Silver Belt, location of some of the world’s historically largest silver producing properties. Crescent Silver is actively and aggressively committed to building a senior silver producing mining company, from expansion of our fully permitted current resource through exploration and acquisition of additional precious metals interests in politically stable mining regions with low operating costs. |

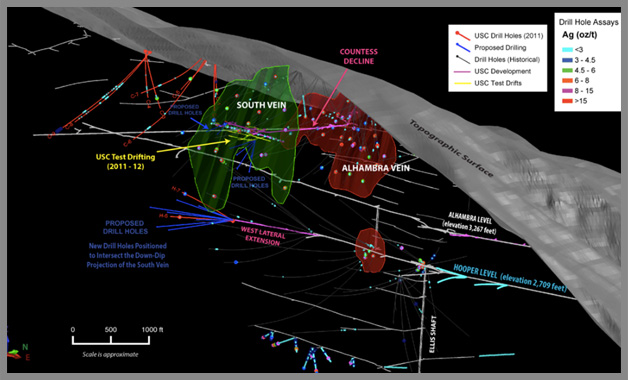

From 2008 to 2012, the Countess portal was completed along with 2,500 feet of decline and 2,200 feet of drift on the Hooper level. Additionally, 2,600 feet of drift were completed on the Big Creek#4 level with plans to connect the Big Creek #4 and Countess portals to create a secondary escape way.

From 2008 to 2012, the Countess portal was completed along with 2,500 feet of decline and 2,200 feet of drift on the Hooper level. Additionally, 2,600 feet of drift were completed on the Big Creek#4 level with plans to connect the Big Creek #4 and Countess portals to create a secondary escape way.